- Sitemap |

- E-mail: samuel@enzarindustry.com

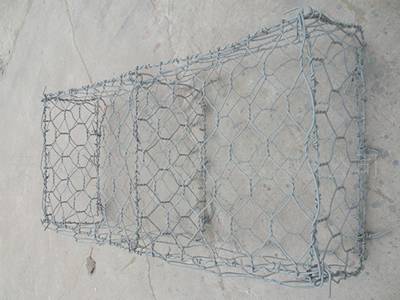

Woven Gabion - Double and Triple Twist for Heavy Duty Application

WG-01: Woven gabion has high tensile strength to resist high impact.

Woven gabions can be made of various corrosive resistant materials and then woven into a series of hexagonal meshes panels. Then the panels are added the thicker selvedge wires for higher loading capacity and durability. Different part of woven gabions are attached together by the lacing wire.

Woven gabions are a type of classical products used in the river bank protection and flood controlling applications. Compared with welded gabions, there are no welding point, which can resist the erosion from flood and sea water. Additional, the twisted structure can supply higher tensile strength to be used in the heavy duty applications.

Woven gabion classification

- According to the material

- Galvanized woven gabions. According to different zinc coating weight, galvanized woven gabion can be divided into electric galvanized and hot dipped galvanized. Heavier the zinc coating weight, better corrosion resistance performance.

- PVC coated woven gabions. The thicker PVC coating supplies outstanding corrosion and rust resistance performance for the gabion box. The inner wire can be carbon steel wire or galvanized wire.

- Galfan woven gabions. Galfan woven gabion refers to 5% aluminum - zinc alloy material gabion. When the gabion in the corrosive environments, the surface will form a oxidation film to resist corrosion and rust.

- 10% aluminum - zinc woven gabions. Higher aluminum content supplier better corrosion resistance than the Galfan woven gabions. It is suitable for high corrosive environments, though the price is higher than the galvanized woven gabions.

WG-02: Galvanized woven gabion.

WG-03: PVC coated woven gabion. - According to twist type

Woven gabion is made of various materials wires and then twisted into hexagonal mesh types. the woven gabion can be different twist types.- Double twisted. Double twisted woven gabion is the common seen and most widely used type. It can satisfy the common applications in the project.

- Triple twisted. Triple twisted woven gabion has higher tensile strength and stability than the double twisted woven gabion. It is suitable for heavy duty applications.

WG-04: Double twisted woven gabion.

WG-05: Triple twisted woven gabion. - According to the gabion height

Woven gabion can be made into different lengths, widths and height. According to different height of the gabion, it can be divided into different types.- Gabion box. gabion box refers to the gabions with 1 meter or higher gabion height. It is widely used for retaining wall applications.

- Reno mattress. The gabion mattress has the height no higher than 0.5 meter. The lower height of the gabion make it suit more applications, such as slope protection, river bank protection and riverway controlling applications.

WG-06: Woven gabion box.

WG-07: Woven gabion mattress.

Specifications of woven gabions

- Material: galvanized wire, PVC coated wire, Galfan wire, 10% aluminum - zinc alloy wire.

- Wire diameter:

- Mesh wire diameter: 2.0 mm - 4.0 mm.

- Selvedge wire diameter: 3.0 mm - 4.4 mm.

- Lacing wire: 2.2 mm.

- Mesh size: 6 cm × 8 cm, 8 cm × 10 cm, 10 cm × 12 cm, etc.

- Length: maximum 6 m.

- Width: maximum 3 m.

- Height: 0.17 m, 0.21 m, 0.3 m, 0.5 m, 1 m, 1.5 m, etc.

Features of woven gabion

- Good corrosion and rust resistance.

- Various specs for choice.

- Different materials for different budget.

- Different height for different applications.

- Suitable for any harsh environments.

- High tensile strength for heavy duty applications.

Applications of woven gabion

- Retaining wall.

- Riverway controlling.

- Slope protection.

- Coastal protection.

- Bridge protection.

WG-08: Woven gabion is used as retaining wall.

WG-09: Woven gabion is used as channel lining.

WG-10: Woven gabion is used for river bank protection.

WG-11: Woven gabion is used for bridge protection.