- Sitemap |

- E-mail: samuel@enzarindustry.com

Galfan Gabion - Double Corrosion and Rust Resistance Performance

GG-01: Galfan gabion is widely used for riverway protection.

Galfan gabion, also called zinc-5% aluminum-mischmetal, Zn-5 Al-MM alloy-coated gabion, is one of the most important corrosion resistant gabion. It is widely used for channel lining, coastal protection, revetment and other protective applications.

The Galfan coating are through a two-step coating operation. The first step is zinc coating, which can be hot dipped galvanizing or electric galvanizing. And then the final bath shall contain at least 7.2% of aluminum to prevent depletion during treating.

Advantages of Galfan gabions

- Smooth surface. The coating is continuous, uniform and smooth and without particles and burrs. During using, it is very safe to operate for people and will not hurt workers. Besides, the smooth surface can make the gabion beautiful and bright.

- Better corrosion resistance performance. When the Galfan gabion in the corrosive environments, the aluminum layer will form a oxidation layer to resist the corrosive element, when the oxidation layer is broken, there still have zinc coating to protect the gabion. So it has better corrosion resistance performance than the galvanized gabions.

- High tensile strength. Made of high tensile strength steel wires, the Galfan gabion can supply stability and durability even in the harsh and high impact applications.

- Ecological. The Galfan gabion is non-toxic and no harm to the soil, water and surrounding environments. Additional, the Galfan gabion can ensure the good circulation of air, water and sunlight to ensure the healthily growth of plants.

- High benefit and value. The cost of Galfan gabion is slightly higher than the galvanized gabion, but the better corrosion resistance performance and longer service life make the gabion be worthy for the cost.

Styles of Galfan gabion

Galfan gabion can be made into different styles and specs to suit different applications. They may different in fabrication technology, mesh structure, gabion height and others.

- Welded type. Welded Galfan gabion adopts Galfan coated wires and then welded into rigid and solid panels with square meshes. The panels are connected by the C rings, U clips, Spiral wires or lacing wires. The welded type Galfan gabion is commonly used in the decorative applications:

- Fireplace.

- Retaining wall.

- Landscape construction.

GG-02: Welded Galfan gabion as retaining wall.

GG-03: Welded type Galfan gabion. - Woven type. Woven type Galfan gabion is the most widely used type. the Galfan wires are woven into a wire mesh panel with hexagonal meshes. Different sizes of panels are combined into cages to load stones or soils. The woven Galfan gabion is commonly used in the protective applications.

- Retaining wall.

- Channel lining.

- Revetment.

- Flood controlling.

- Coastal controlling.

GG-04: Woven type Galfan gabion.

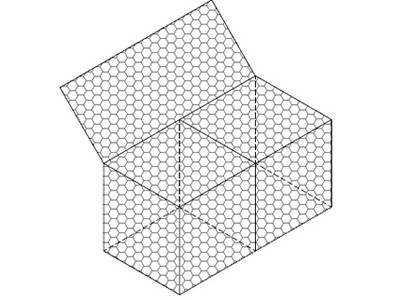

GG-05: Woven Galfan gabion as retaining wall. - Gabion box type. Commonly the height of gabion box is 1 meter and maximum is 1.5 m. If you need higher gabions, just pile the gabions up to your needed height. Gabion box is widely used in the channel lining and retaining wall applications. It is high strength and solid enough to defend the external forces.

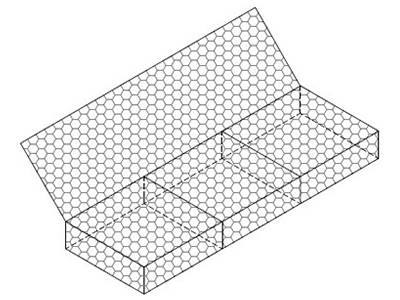

- Gabion mattress type. Gabion mattress refers to the gabion with no higher than 1 meter. And the common height is 0.17 meter to 0.5 meter. Special sizes can be customized. Compared with gabion box, the gabion mattress is more flexible to be used in the riverbank protection, slope protection and other applications.

GG-06: Galfan gabion box.

GG-07: Galfan gabion mattress. - Double twist type. Double twist is the common and ordinary type of structure. It is solid enough to suit the common applications. It is more economical than the tripe twisted Galfan gabion. In the same wire diameter and mesh size, it will save the materials and the weight of products is lighter than the triple twist type. So you can not only save the material cost and freight cost.

- Triple twist type. Triple twisted Galfan gabion can supply you higher tensile strength and stability to the gabions. It is suitable for heavy duty applications to defend the high impact from external force, such as flood, tidewater and other forces.

GG-08: Triple twisted Galfan gabion.

GG-09: Double twisted Galfan gabion.

Specifications of PVC coated gabion

- Material: low carbon steel wire PVC coating or galvanized wire PVC coating.

- Mesh wire diameter: 2.0 mm/3.0 mm - 3.0 mm/4.0 mm.

- Selvedge wire diameter: 3.4 mm/4.4 mm.

- Lacing wire diameter: 2.2 mm/3.2 mm.

- Mesh size:

- Woven type: 60 mm × 80 mm, 80 mm × 100 mm, 100 mm × 12 mm and so on.

- Welded type: 1/4", 1/2", 3/8", 3/4", 1", 2", 3", etc.

| Item | Length (m) |

Width (m) |

Height (m) |

Number of cells |

|---|---|---|---|---|

| GGS-01 | 2 | 1 | 0.17 m 0.23 m 0.3 m 0.5 m 1 m 1.5 m |

2 |

| GGS-02 | 3 | 1 | 3 | |

| GGS-03 | 3 | 2 | 6 | |

| GGS-04 | 4 | 1 | 4 | |

| GGS-05 | 4 | 2 | 8 | |

| GGS-06 | 5 | 1 | 5 | |

| GGS-07 | 5 | 2 | 10 | |

| GGS-08 | 6 | 1 | 6 | |

| GGS-09 | 6 | 2 | 12 | |